Reverse Logistics

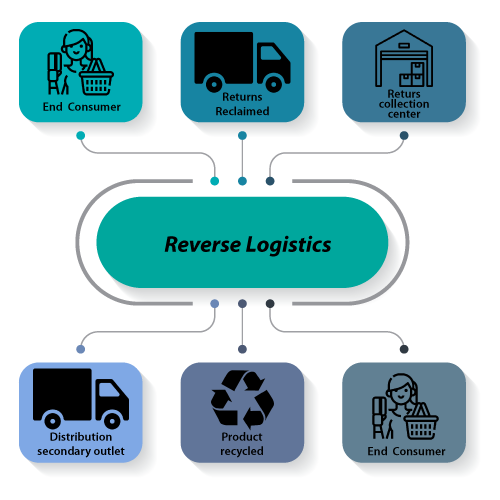

The ever-growing market pressure is causing strain on the supply chain. Companies that intend to gain optimum value and efficiently adapt to the market demands should not overlook reverse logistics. Reverse logistics definition points toward a set of activities that travels backward through the supply chain. It is performed to fulfill various purposes, whether to capture the product’s value, re-use or ensure its proper disposal. It allows stakeholders to gain value, reduce waste, and enable cost savings.

Request a Pickup

Since the process is complex, organizations often choose to outsource support from reverse logistics companies. The third-party service provider offers custom-built reverse logistics solutions to streamline the process. The entire workflow must be strategically defined to avoid any incompetency. It will help extract the optimal value when a product reaches the end of its lifecycle. Here are a few things to develop a strong understanding of reverse logistics.

What does reverse logistics mean? How does it work?

What is reverse logistics? Reverse logistics is a part of supply chain management. It helps in moving the products back from customers to the seller/manufacturer. It allows companies to regain their value or ensure their disposal. The process operates involving the following 5 R’s

· Return

· Resell

· Repair

· Repackage, and Recycle.

When is reverse logistics used?

Reverse logistics comes to use when goods need to move backward from the destination. They travel ‘reverse’ in the supply chain to the seller. And they may potentially reach the supplier. It enables product retrieval. Based on its condition, reverse logistics experts determine if they can refurbish it or extract parts and dispose of it.

Schedule Pickup

If you have any questions or queries about IT equipment buyback services, feel free to contact us by Telephone, Email, or Requesting a Quote. We'll be happy to assist you.

Types of Reverse Logistics?

Reverse logistics management is of various types. According to your requirements, you can outsource reverse logistics services for better management. These professionals leverage best practices to ensure that it is correctly handled. It ensures optimum ROI. Take a look at the different categories of reverse logistics.

Returns Management

It involves defined practices to ensure that the product is returned to the organization from customers. It ensures that the product arrives back at the right entity. Establishing a robust return management pipeline and policies is crucial to ensuring customer satisfaction.

Advantages Of Reverse Logistics

Reverse logistics is of crucial importance in facilitating customer satisfaction. Simplification of return processes enhances business credibility and reduces waste. Moreover, it helps companies regain products’ value by refurbishing or recycling them. Efficient reverse logistics reduce inherent risks in completing the product lifecycle.

Refurbishing Or Remanufacturing

It implements activities to repair and rework the goods. It prepares the products for the shelves again. Based on their condition, it defines the complexity and scope of remanufacturing process for companies.

Return Policy And Procedure

Return Policy and Procedure (RPP) lays out guidelines in customer contracts, defining what permits a return. It must be accessible, visible, and unambiguous. The clients should also align with the companies’ established RPP.

Procedures For Returning Items

Defined procedures enable companies to smoothly process reverse logistics. It helps properly authorize returns by verifying the goods' condition. It also covers activities to schedule the return supply chain and approve refunds.

Management Of The Packaging

The reverse logistics is hinged on the key idea of waste reduction. Thus, the product is recovered along with the packaging material. These materials are re-used to reduce waste or ensure proper disposal.

Goods That Were Never Sold

Sometimes the extra stocks at the retailers do not get sold. Or when end customers do not receive or refuse the goods, it results in unsold goods. In such situations, efficient reverse logistics must be in place to bring it back to manufacturers/distributors.

End-Of-Life (Eol)

A product that has reached the end of its lifecycle becomes redundant. Customers no longer need it and choose to replace it. Reverse logistics enable manufacturers to repossess such goods. They either choose to scavenge it to retrieve parts, recycle it, or carry out their proper disposal.

Items That Were Not Delivered

Due to failed or missed deliveries, end customers do not get the product. Such goods arrive back at the sorting warehouse. It then travels back to the starting point. Accordingly, stakeholders determine what to do with the product.

Leasing And Rentals

Customers use certain equipment according to the terms of leasing/rental contracts. When the lease period is over, stakeholders tend to reclaim it via reverse logistics. They then decide what to do with the used product.

Maintenance And Repairs

According to Service Level Agreement, the enterprise provides customers with repair and management services for the purchased goods. If the product requires repair, the reverse logistics process helps to bring back the product to the manufacturer.

Schedule Pickup

FOR OLD EQUIPMENT

FAQ's

What is meant by reverse logistics? Can you give some examples?

Reverse logistics meaning implies the backward movement of the supply chain. It moves items from customers to the seller/manufacturer. It serves various purposes, such as to re-capture a product’s value, re-use it, or properly dispose of it. Among reverse logistics examples, it covers mobile companies. When customers want to upgrade their mobile phones, companies offer discounts on new products if customers re-sell their old ones. These old models are brought to factories to retract working parts and ensure proper disposal.

Is it good to work with a reverse logistics partner? Why?

The reverse logistics process is complex. Working with a reverse logistics partner helps establish an efficient, cost-effective system. They have adequate knowledge and expertise to conduct various activities. These partners can track product value and movement, handle inspection and repairs, and deal with recycling and disposal.

How can high-quality reverse logistics be guaranteed?

We have established a full-proof reverse logistics process that we customize to your needs. We have an established network to ensure cost-effective movement of logistics. We have access to the necessary skills, equipment, and infrastructure to design, test, manage returns, handle end-of-life products and their packaging, and recycle or dispose of them to make the process faster, efficient, and profitable.

What price scheme do you employ?

Reverse logistics is required in your company for various reasons. The cost impact of reverse logistics is high. But with us, you do not have to worry. Based on the type of services you require, we determine the costs. According to the details you will provide, we offer you an instantaneous quote. Our goal is to help you regain maximum value by refurbishing or recycling the product and ensuring environmental safety.

How quickly can you handle returns?

Our team will work closely with you to manage returns. We address the challenges and immediately get to work to initiate the return management process. Based on your Return Policy and Procedures (RPP), we help you to quickly move through it.

How does reverse logistics help to minimize product returns?

Reverse logistics is required because it brings down instances of product returns. When you provide customers with a sound return policy, it helps improve their trust and satisfaction. If the reverse logistics and return process is simple and transparent, they will be happy. Thus, your business will become more profitable, and you can retain revenue.

What’s the difference between reverse logistics & circular supply chains?

A circular supply chain prompts sellers/manufacturers to recycle discarded materials for resale. Reverse logistics serve various purposes. It is used for returns management, end-of-life products, maintenance and repairs, and managing packaging among others. The goal is to reduce waste, regain value, optimize customer experience, and minimize waste.

How much does reverse logistics cost?

Once you put your request on our platform and provide the necessary details, we will provide you an immediate quote. It is transparent, with no hidden costs. We provide you with the best, cost-efficient services to help you maximize your ROI.